At Signals in Motion, we specialise in optimising these processes to drive growth and cut costs. Our expert consultants conduct in-depth analysis of your entire production and operational flow.

We identify bottlenecks slowing output, inconsistencies affecting quality, manual processes that can be automated, and waste that can be eliminated.

Based on this assessment, we develop an optimisation plan tailored to your operational needs and production goals.

• Automation, robotics and AI to boost efficiency

• Lean initiatives like Six Sigma and Just-in-Time to remove waste

• Process improvements to increase speed and yield

• New technologies like IoT sensors for real-time monitoring

• Data-driven systems for supply chain transparency

• Advanced analytics and simulations to optimize operations

• Sustainability best practices to manage your environmental footprint

• Renewable energy sources to reduce emissions

• Closed-loop recycling to minimise waste

• Inventory management enhancements to cut waste

• Quality assurance changes to improve consistency

• Changes to plant layout and workflow for smoother flow

We can also deliver training and change management support to smooth the implementation process. And post-implementation, we continue monitoring your metrics to ensure optimisation is sustained long-term.

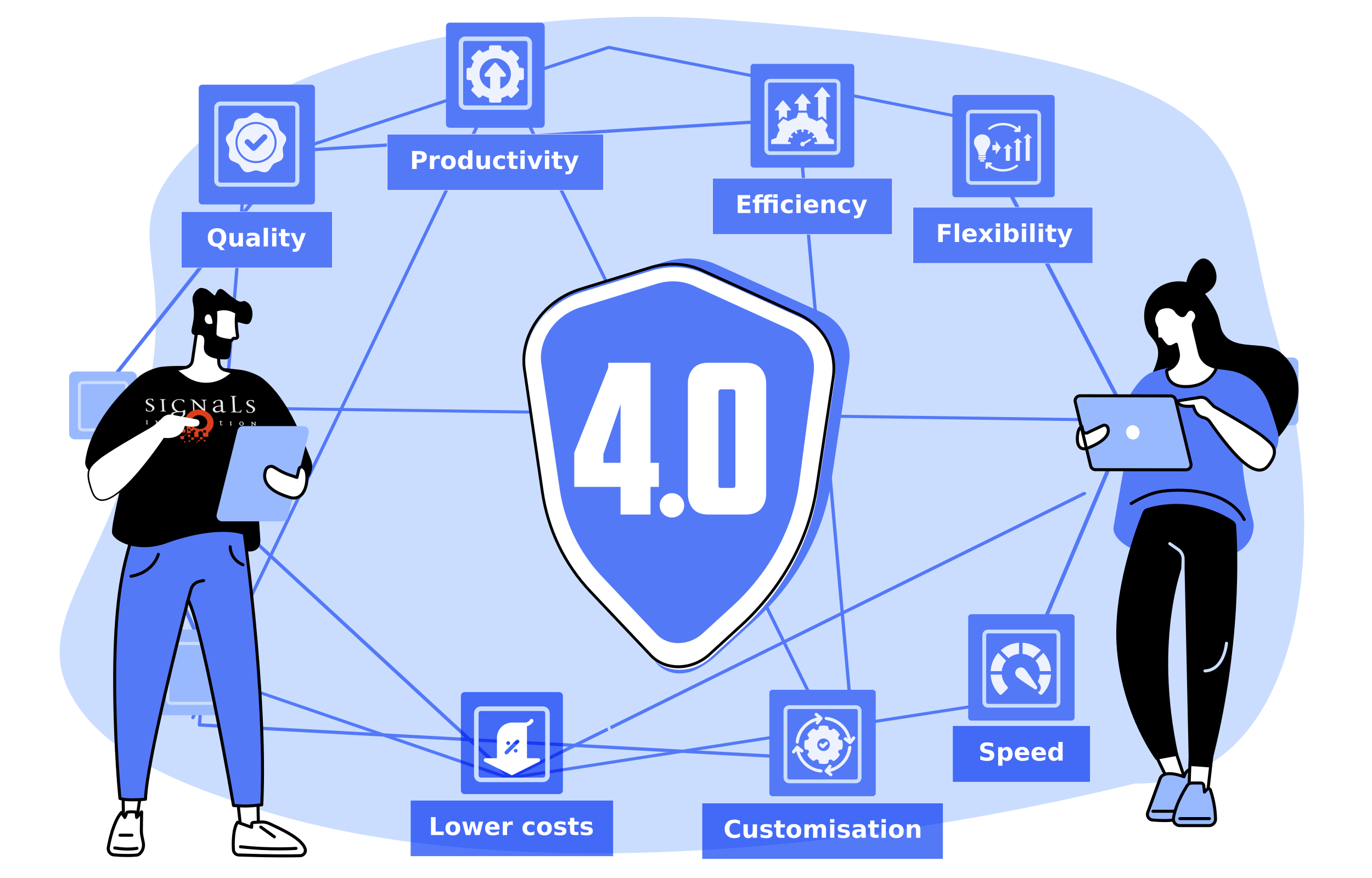

The benefits for your company are far-reaching. They can include increased throughput and capacity, faster production times and turnaround, lower operational costs and less wastage, improved product quality and consistency, enhanced decision making from data insights, and reduced environmental impact.

You have probably already made changes in your business related to the digital transformation of industry, sometimes called Industry 4.0. In jargon-free language, this is a set of changes that could mean connecting the factory to the point of sale, or better analysis of production data to improve manufacturing, distribution and after-sales. Consult us to leverage new technologies to drive your competitive advantage.